as an elaborated product

and the earliest

forms of roasting

In the seventh century, Arab trade was already established at both a local and international level.

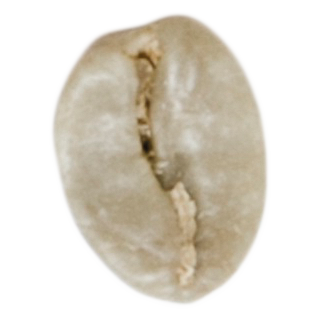

Coffee seeds were circulated via different routes, largely overland or along rivers. Because the fresh product was so perishable, it had to be transported as quickly as possible.

In the late medieval period, trade relations between Ethiopia and the peoples of the southern Arabian Peninsula intensified notably, allowing the introduction of the plant and its earliest cultivation in what is now part of Yemen.

Between the thirteenth and fourteenth centuries plants were more often used in domestic elaborations and coffee made its historical debut as an energy-giving and medicinal spice.The first coffee-based beverages were produced by simply boiling the beans or the whole fruits, or even using the leaves.

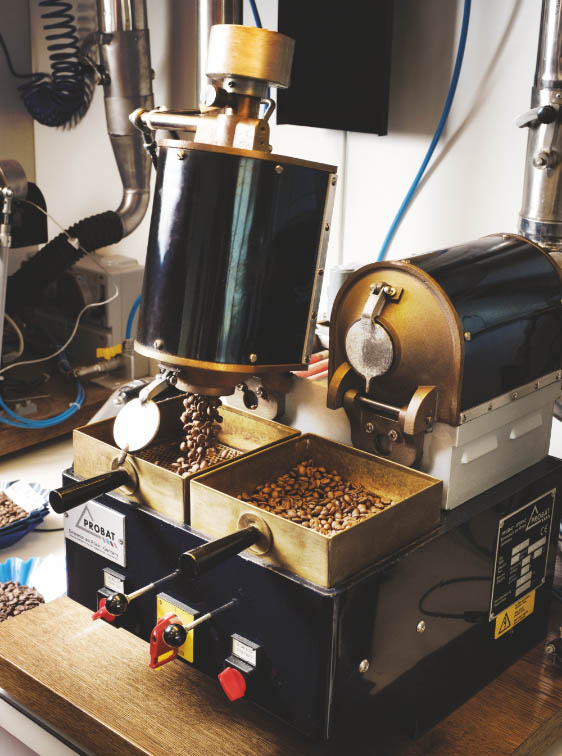

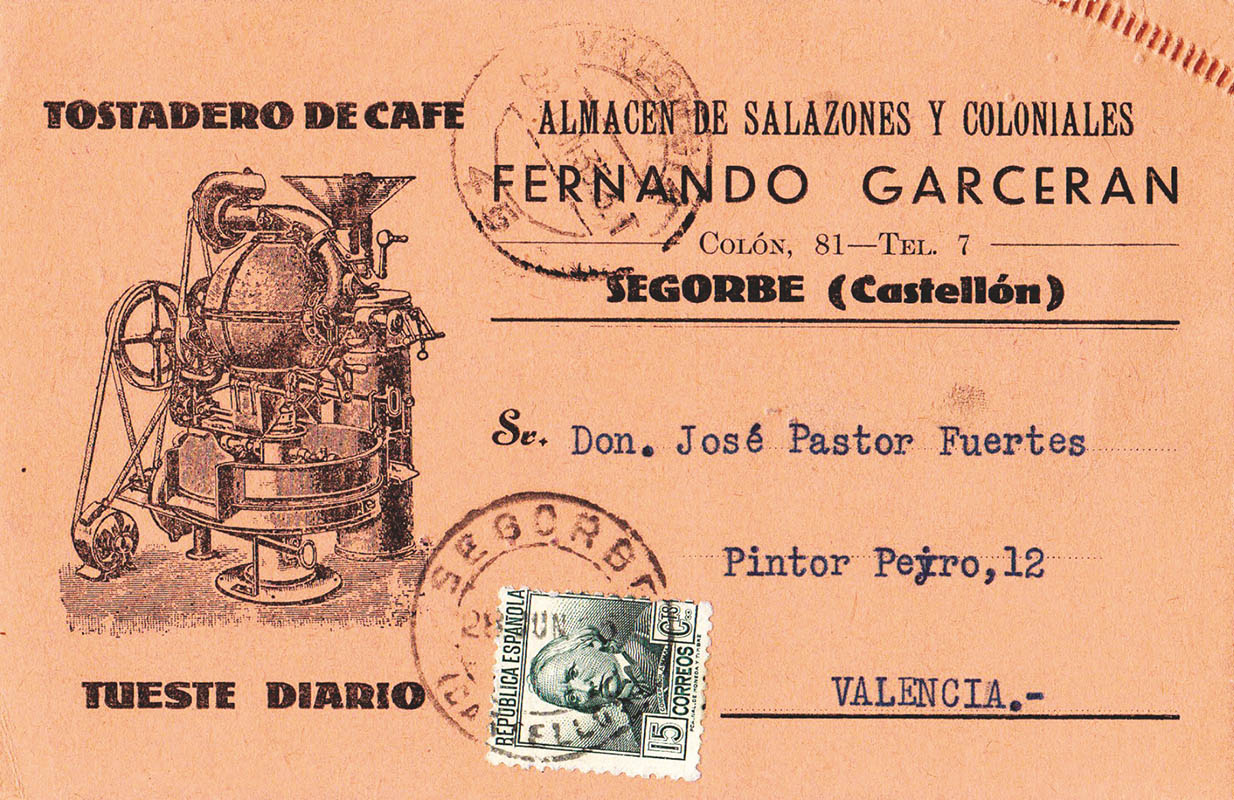

The first known instruments for roasting coffee beans were almost certainly slender metal or earthenware pans, round in shape and often with holes, which went on to become widespread in the fifteenth century across the Ottoman Empire and Greater Persia.

roasting and the

conquest of Europe

Muslim pilgrims and traders introduced coffee throughout the Islamic world (Persia, Egypt, Turkey, North Africa), turning it into a highly desirable and economically profitable product.

The Arabs consolidated their position as the only exporters to North Africa and the Ottoman Empire. This monopoly was so important to them that merchants were forbidden to transport beans to other countries unless they had been dried or boiled to destroy their capacity to germinate.

The first encounters between Europeans and coffee took place towards the end of the sixteenth century, a time when trade with Arab and Turkish merchants thrived (particularly in Venice, Marseilles and Izmir).

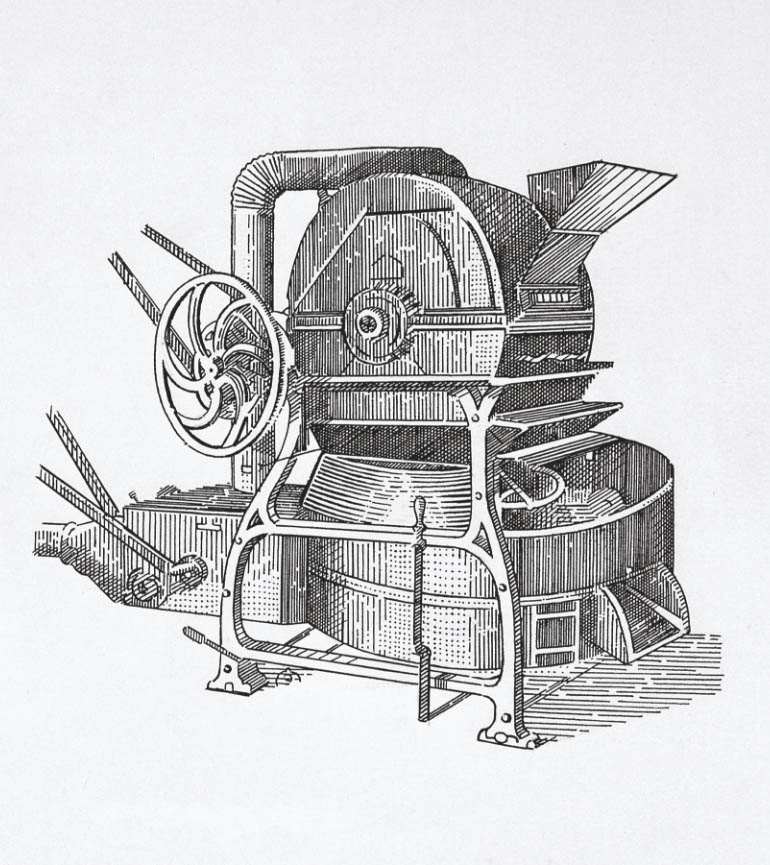

Beginning in the second half of the seventeenth century, with the growing success of cafés, coffee houses and shops in Europe, larger machines were being used for roasting.

in the Age of Enlightenment

The coffee was introduced to the court of Louis XIV. The king enjoyed both the beverage and its preparation. During the period when the colonies were at the peak of their splendour, the French dedicated themselves to producing tools for roasting.

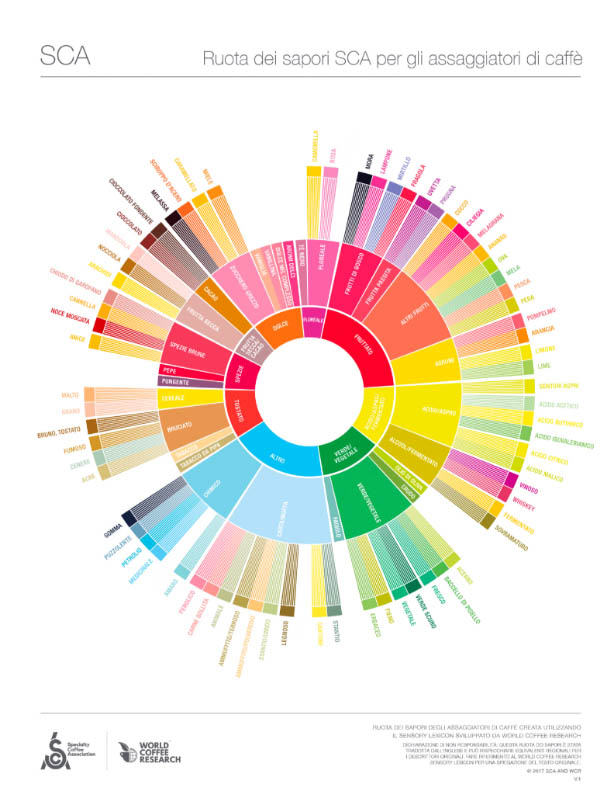

The first sales names, such as ‘Java’, ‘Mokha’ and ‘Bourbon’, began to appear. Different varieties are associated to specific characteristics and trade values.

The classification and standardisation of the raw product became an activity carried out by traders, who created categories which could, in turn, influence consumers.

Accompanying the spread and huge success of cafés in the busiest European cities came the adaptation and refinement of tools for roasting and grinding. The size of these tools was adapted to suit the size of the public places which began to roast coffee on-site and serve large numbers of beverages every day.

fruit and the bean in an

industrial society

The most frequently used method to process the fruits was the drying method. It can be assumed that the wet processing method has been introduced to the East Indies towards the end of eighteenth century.

Thanks to the English, who during the nineteenth century exported various elements of their coffee apparatus, the coffee roasting industry made great advances, including in the United States.

and innovations in

roasting

An unprecedented development in the machines took place. German, French, American and English inventors made continuous improvements to the roasting and grinding processes.

From the 1870s, the earliest models of gas roasting machines began to be developed. The first machine capable of roasting, grinding, weighing, packaging and labelling coffee in small paper parcels was invented by the American entrepreneur John Arbuckle and patented under the name of ‘Arbuckle Ariosa’.

1889

Carl Salomon from Braunschweig introduced a quick-roasting technique using the principle of hot gas ventilation that reduces the duration of roasting to 20 minutes. Achieving quick roasting was always the main objective of European entrepreneurs.

XIX - XX Century

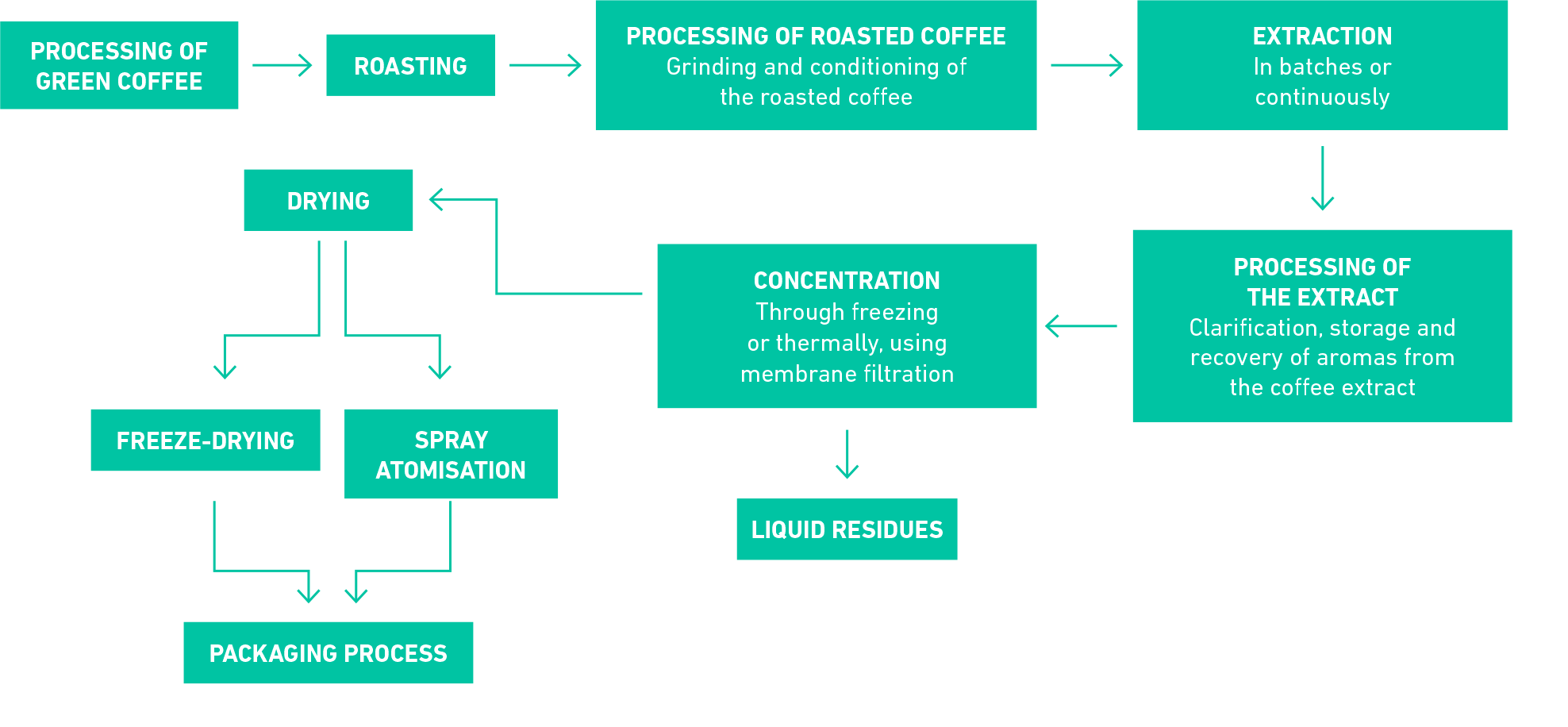

Around the turn of the century, the earliest attempts to create instant coffee were recorded. The first patent for instant coffee was filed in 1881 by the Frenchman Alphonse Allais.

The practice of home roasting fell into disuse. A number of entrepreneurs sought to provide the consumer with high-quality roasted coffee (sometimes even ground), eliminating the bother of roasting it at home.

1900

R. W. Hills invented the vacuum-packing process, which removed air from coffee packets and allowed people to have a fresher elaborated product.

to post-World War Two

Thanks to the tireless work of inventors, mainly Germans and Americans, the sector underwent further growth before the two world wars and prospered again in their wake. Coffee processing on plantations reached ever higher levels of precision during the first decades of the twentieth century. Proof of this can be found in the number of innovations that were patented during this period in relation to machinery for the various stages of processing.

1903

At the beginning of the twentieth century, the first models of electric roasting machines were patented. One of the first, from 1903, was the work of George C. Lester from New York. Its main advantage lay in the elimination of the smoke and vapours that could imbue the coffee with unpleasant smells and flavours.

Despite reduced consumption of coffee due to more restrictive policies on imports and the periods of war, roasting became a lucrative business, depending on the resources available.

Late Nineteenth Century

In large plants, industrial machines were used for grinding and others for the packaging process, with their own designated areas inside the plants. From lowest to highest, the grind could be coarse, medium, fine, very fine and powdered.

1920 / Packaging

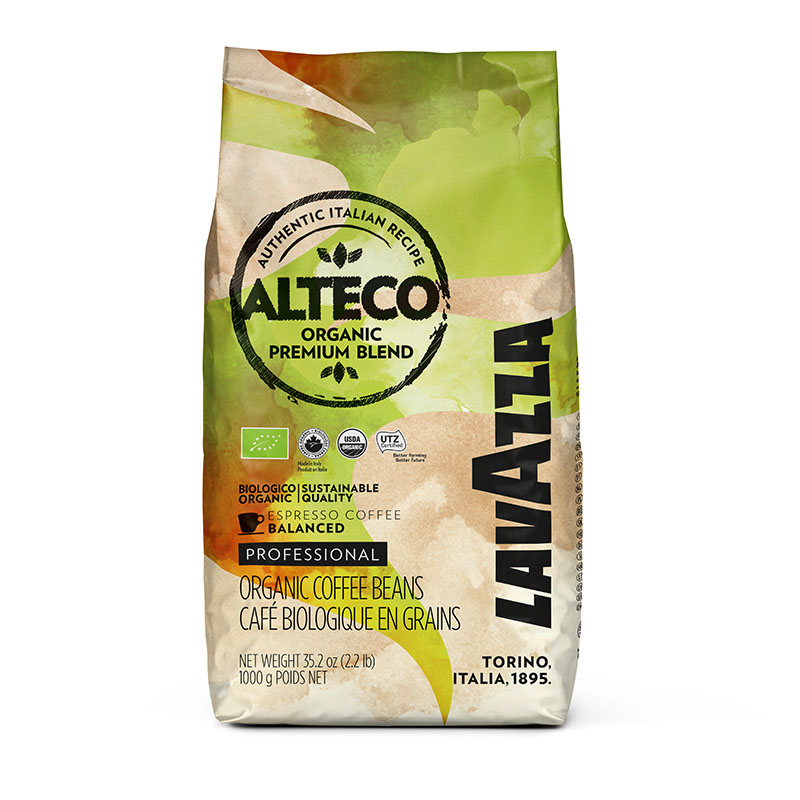

In the 1920s Lavazza began to use Pergamin, a form of packaging consisting of two layers of paper. During the first decades of the twentieth century, it was fashionable to have blends of different coffees specially created for a certain hotel, bar or restaurant. Mechanisation also provided a significant boost in the production of continuous-cycle machinery used during the packaging process for the whole or ground final product.

agreements

The years following World War Two can be described as the era in which attempts were truly made to regulate the global coffee trade.

At the beginning of the 1950s, the leading European coffee roasters dominated the market, as they had during the Great Depression in America. The verticalisation of the production process aimed to guarantee a level of quality that could be reproduced in increasingly diversified and technical products.

1950s

One of the most highly prized innovations in production has been the use of airless vacuum packing in packaging the elaborated product, beginning in the early 1950s and allowing a longer storage time and wider distribution. During and after the Second World War, freeze-drying processes were developed. They contributed to the popularity of instant coffee.

1963

The International Coffee Organisation was set up under the auspices of the United Nations. The International Coffee Agreement was first negotiated in 1962. The agreement, which was rewritten in 1968, sought to establish the quotas of producing countries and keep coffee prices high and stable on the market.

1971

From 1971, the company from Turin used vacuum-packing packaging for Qualità Rossa.

Then, from the mid-twentieth century onwards, came a boom in patents for domestic electrical appliances for coffee roasting and elaboration. The first speciality coffee houses for aficionados emerged during the 1970s and the following two decades were witness to the growth of the gourmet coffee industry.

1975

The severe frost that hit Brazil halved production with a resulting increase in world prices, which reached a record $3.30 per pound in 1977. Between 1975 and 1976, the terms of a new agreement were negotiated.

1994

A new international agreement is signed to increase international cooperation and to establish a permanent forum that would regulate supply and demand.

1990 / single portion

By the end of the 1950s in the United States, patents had already been filed for a system in which ground pressed coffee would be placed between two layers of filter paper in the precise quantity needed to prepare a cup of espresso with an espresso machine. In Italy in 1998, this system was combined with the dimensions and weight of the soft pod for the ESE (Easy Serving Espresso), a standard which is shared by many roasters.

A vitally important step in the history of capsule coffee was the introduction in 1989 of plastic capsules with the Espresso Point system, the first from the Lavazza brand.

product at the dawn

of the third millennium

At the beginning of the twenty-first century, the global coffee market was dominated by large companies who were leaders in the sector. During these years, the market experienced strong growth, with an emphasis on product quality and the experience of the final consumer.

2004

The coffee was the most exported product in no fewer than twelve countries across the world and the second most exported commodity by value for developing countries from 1970 to 2000.

Concern for sustainability has swept over the coffee production sector as never before, with the consolidation of legislative frameworks designed to regulate the most ecologically and socially delicate aspects of the production industry.